ABOUT US

Focused on Electronic Components Manufacturing for 20 Years.

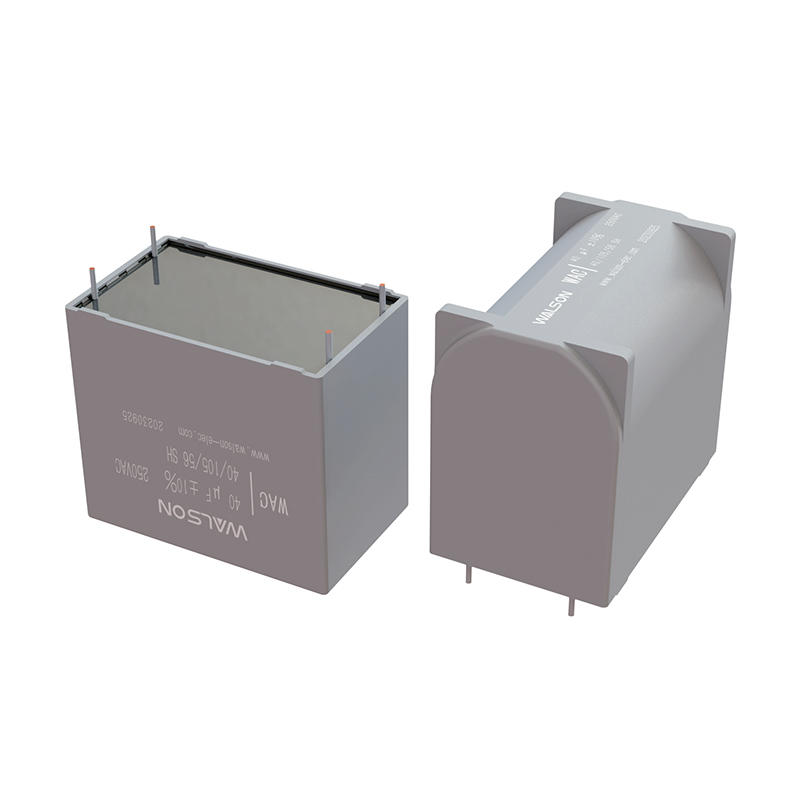

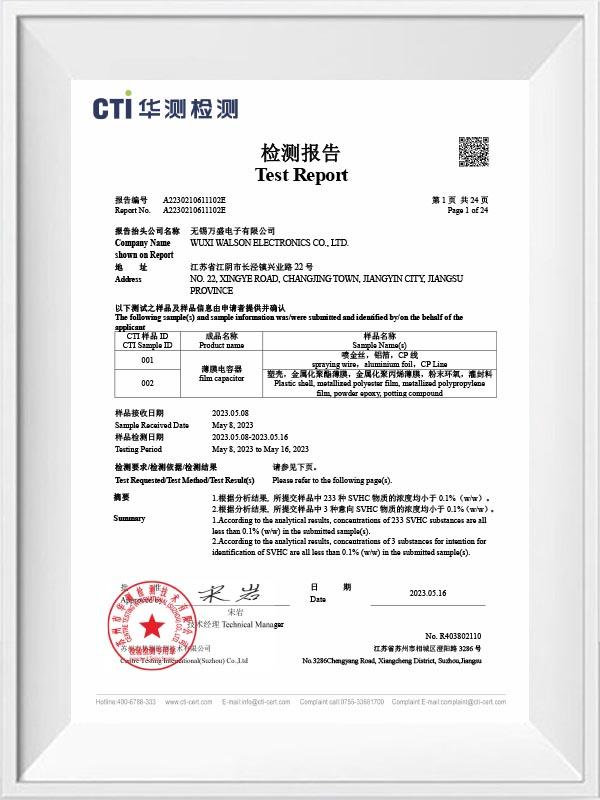

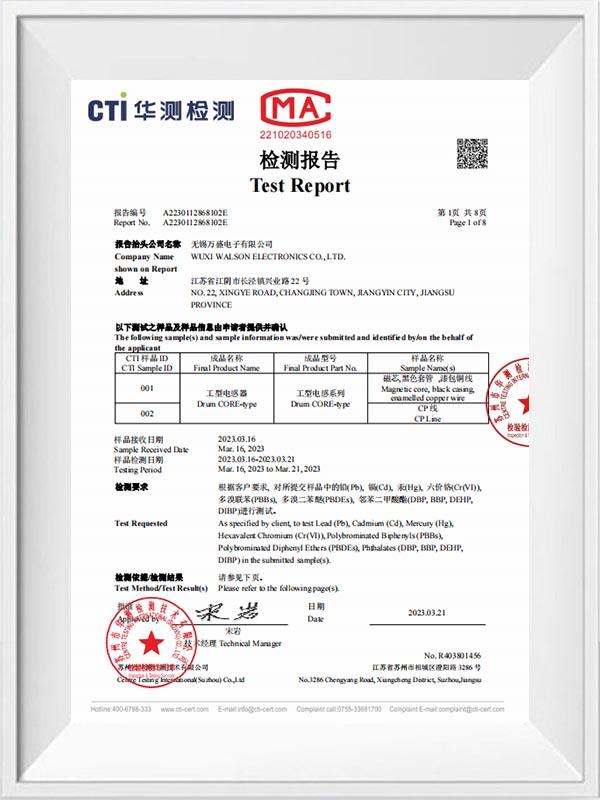

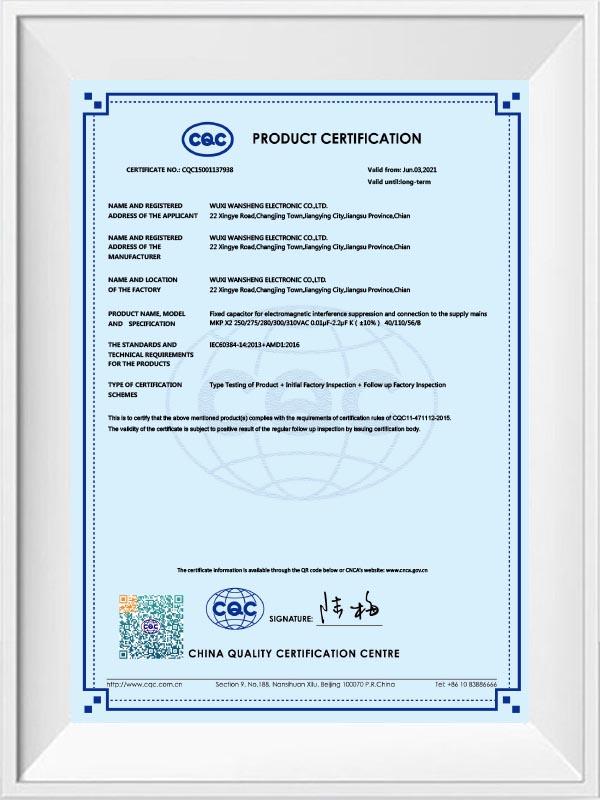

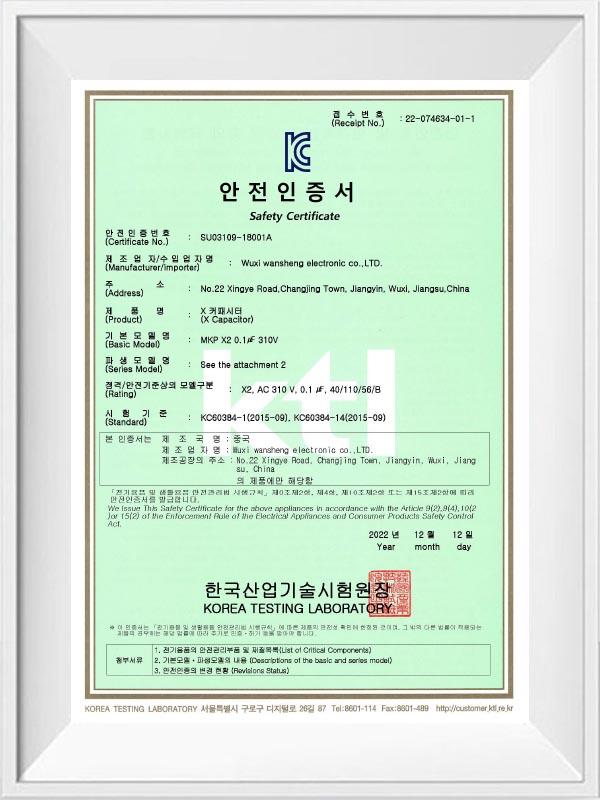

Walson Electronics was established in 2001, with more than 20 years of experience in R&D, manufacturing, sale and service of film capacitors. We are Custom AC Film Capacitor Suppliers and Custom UPS AC Capacitor Manufacturers.

We always adhere to the cooperation of advanced automation and industrialization. the company continues to introduce domestic and foreign outstanding production equipment, while self-developed production management software, enterprise collaborative management to scientific and efficient operation, has achieved 1 billion/annual production capacity breakthrough, and maintains an orderly rise.

Walson Electronics products have covered more industries, including new energy and power industry, Photovoltaic inverters, LED lighting, household appliances and various power sources and other industries.

Adhering to the concept of innovative technology, honest service and professional quality, Walson Electronics pushes forward capacitor products continuously and is sure to become the industry pioneer with innovative advantages.

-

In today's digital era, the demand for electronic products continues to grow, and the demand for high performance, thinn...

READ MORE -

With the increasing global demand for renewable energy and the reduction of traditional fossil energy, the development o...

READ MORE -

In modern society, the stable operation of critical infrastructure is crucial to the normal functioning of society. Thes...

READ MORE -

Smartphones have become an indispensable part of modern life. They are not only communication tools, but also a comprehe...

READ MORE

How do AC filter capacitors differ in construction and performance from DC-link capacitors or other types of power capacitors commonly used in inverter applications?

Dielectric Material:

AC filter capacitors: Typically use polypropylene (PP) or metallized polypropylene (MPP) dielectric materials optimized for high AC voltage applications. These materials offer high dielectric strength, low dielectric loss, and excellent self-healing properties. DC-link capacitors: Often use polypropylene (PP) or metallized polyethylene terephthalate (PET) dielectric materials suitable for high DC voltage applications. These materials offer high insulation resistance and low dielectric absorption.

Construction:

AC filter capacitors: Constructed to withstand high peak AC voltages and current ripple. They may have segmented metallization or heavy-duty construction to handle the high voltage and current stress.

DC-link capacitors: Designed to handle high DC voltage and ripple current. They may have compact cylindrical or box-like designs optimized for high energy storage and low equivalent series resistance (ESR).

Voltage Rating:

AC filter capacitors: Typically have higher AC voltage ratings to withstand peak voltage levels in AC circuits. They are rated in terms of RMS (root mean square) voltage. DC-link capacitors: Designed for high DC voltage applications and rated based on their DC voltage handling capabilities.

Capacitance and Ripple Current:

AC filter capacitors: Selected based on capacitance value and ripple current handling capability to effectively filter out AC noise and harmonics. They are optimized for low impedance at the fundamental frequency and high impedance at harmonic frequencies.

DC-link capacitors: Chosen based on capacitance value and ripple current rating to store and smooth out DC voltage. They are optimized for low ESR and high ripple current handling to minimize voltage ripple in DC circuits.

What thermal management techniques are employed to ensure proper heat dissipation and temperature stability in AC filter capacitors operating under high-power conditions?

Selection of High-Temperature Materials: Using materials with high thermal conductivity and temperature resistance for the capacitor construction can enhance heat dissipation and improve temperature stability. For example, using metalized film with high thermal conductivity can help spread heat more efficiently within the capacitor.

Optimized Capacitor Design: Designing the capacitor with features such as increased surface area or fins can enhance heat dissipation. This can involve optimizing the capacitor's shape, size, and internal structure to maximize airflow and facilitate heat transfer.

Cooling Systems: Implementing active or passive cooling systems, such as fans, heat sinks, or thermal pads, can help dissipate heat generated during capacitor operation. These cooling systems can be integrated into the capacitor assembly or the surrounding electronic system to maintain optimal operating temperatures.

Placement and Mounting: Proper placement and mounting of AC filter capacitors within the electronic system can also affect thermal management. Placing capacitors in locations with good airflow and minimal heat buildup can help dissipate heat more effectively.

Additionally, using thermal interface materials between the capacitor and mounting surface can improve heat transfer.

简体中文

简体中文 English

English Español

Español