ABOUT US

Focused on Electronic Components Manufacturing for 20 Years.

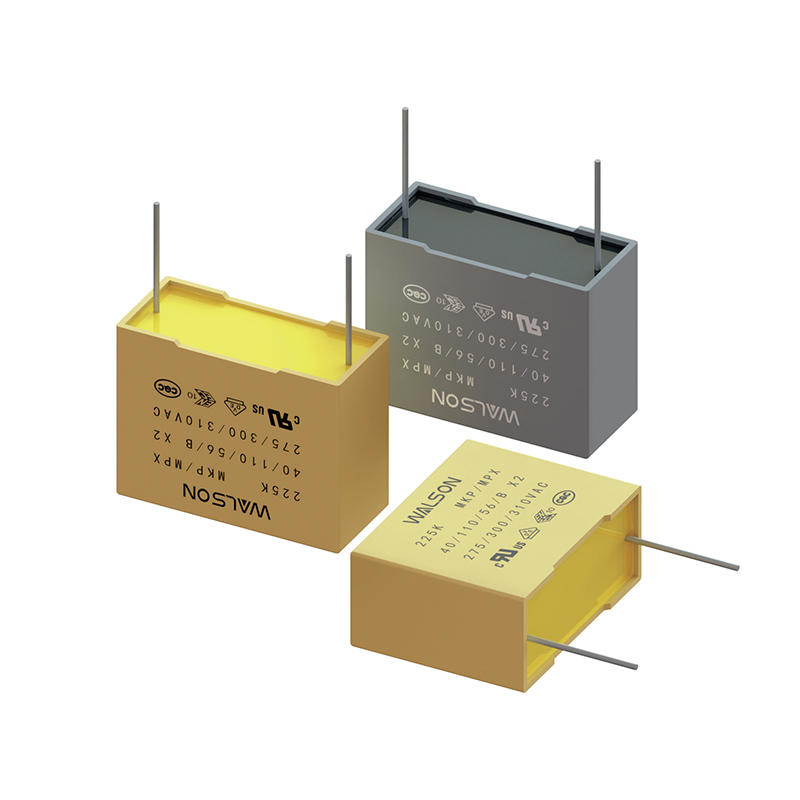

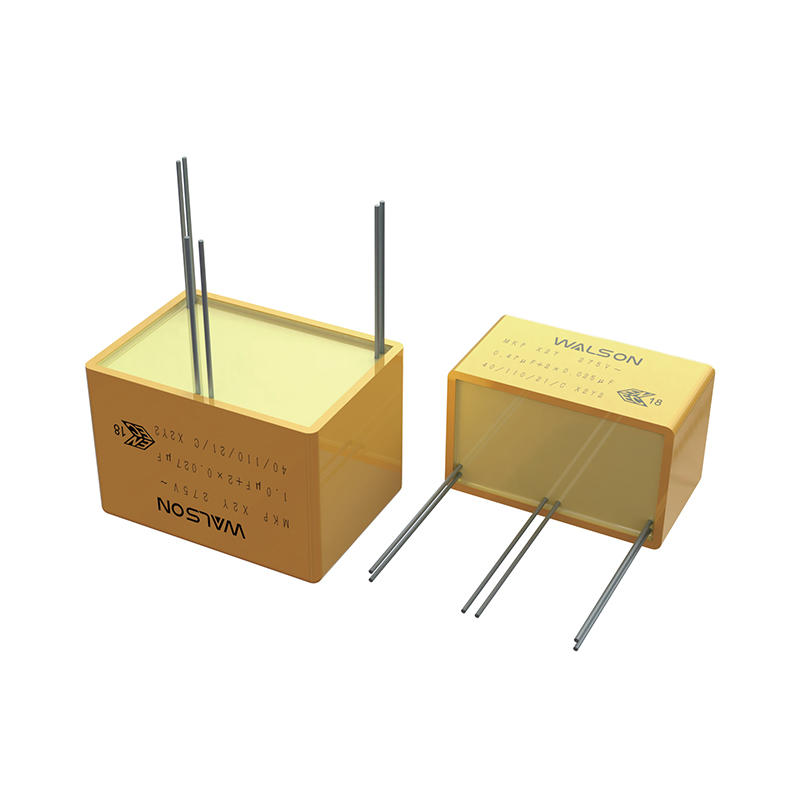

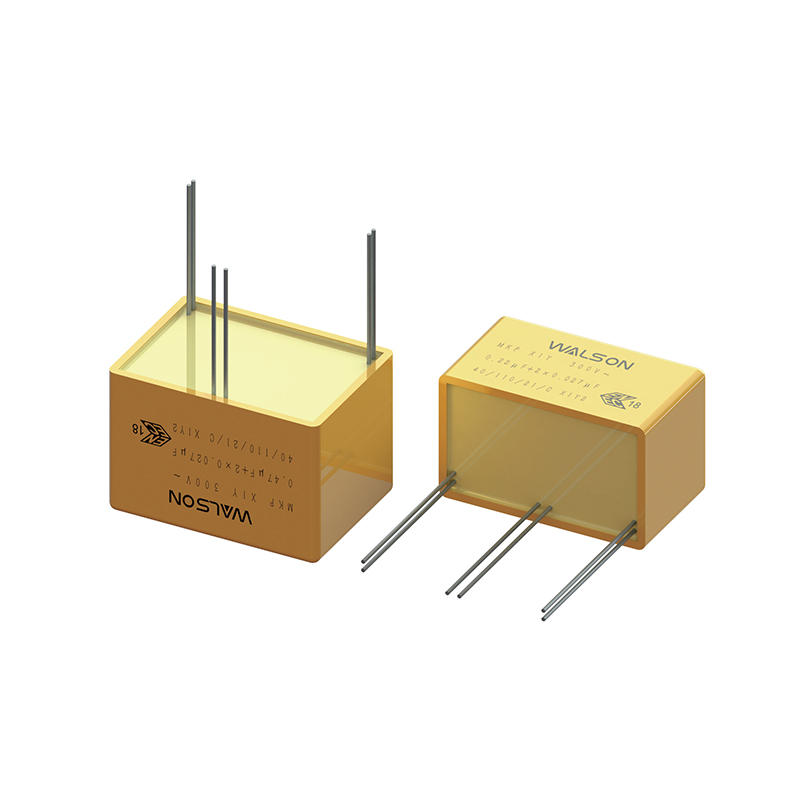

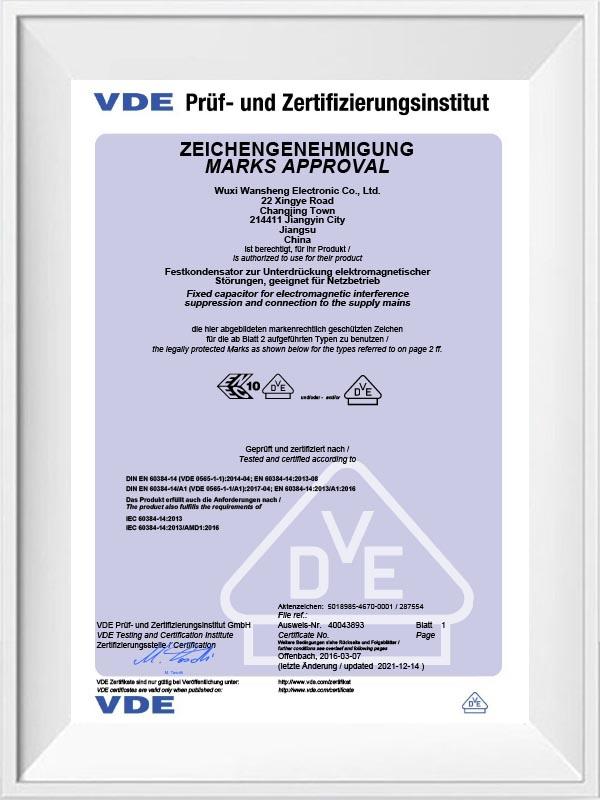

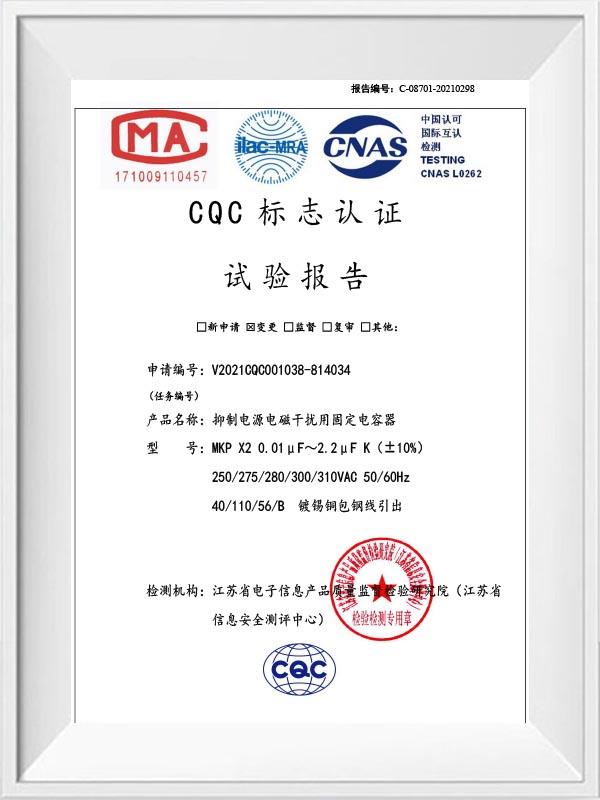

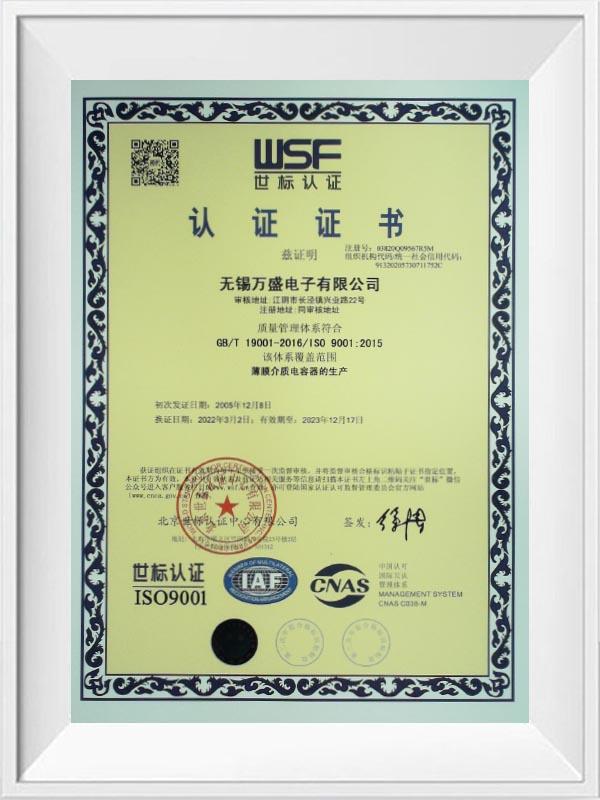

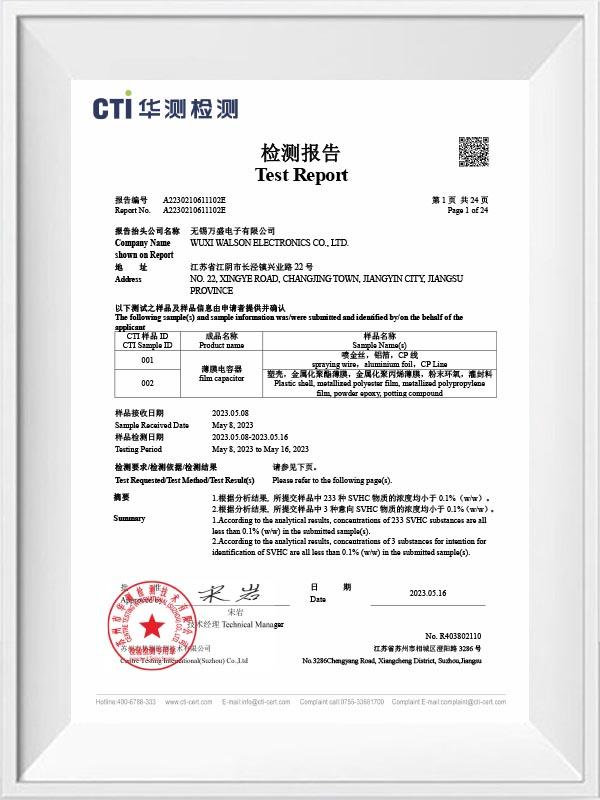

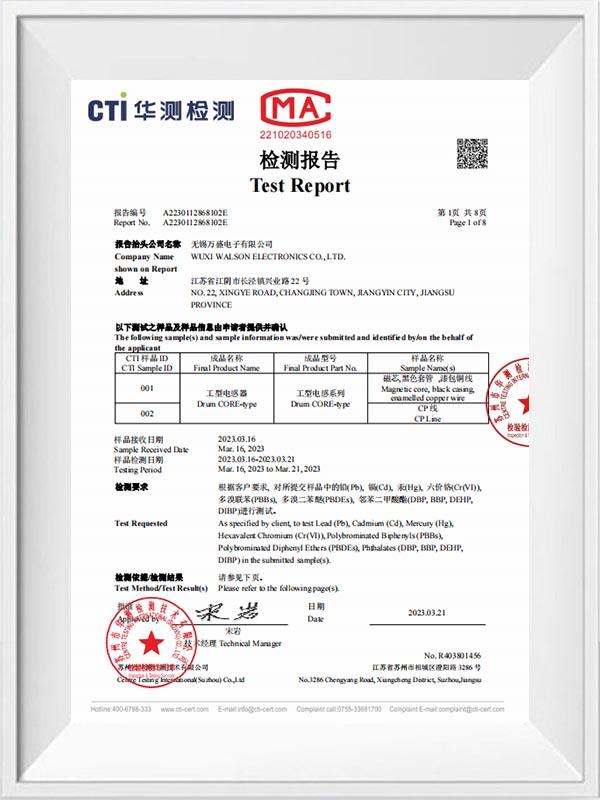

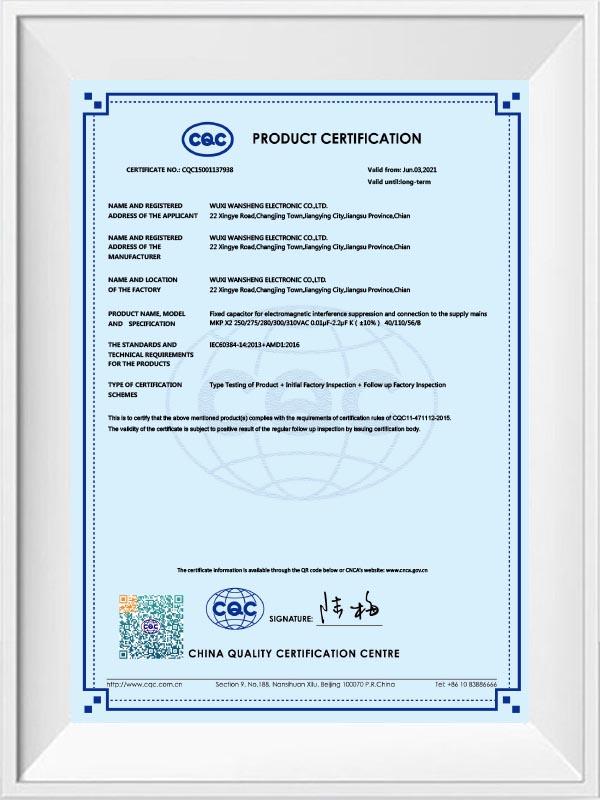

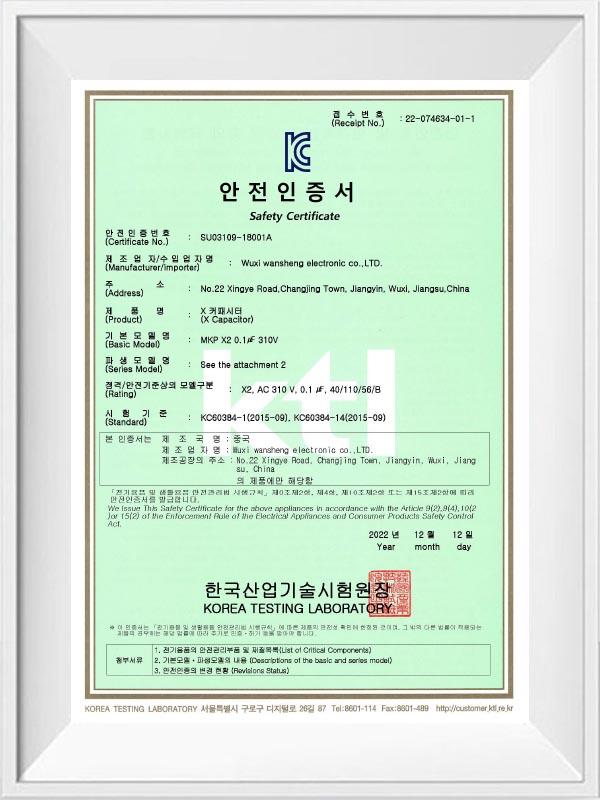

Walson Electronics was established in 2001, with more than 20 years of experience in R&D, manufacturing, sale and service of film capacitors. We are Custom X2 Film EMI Capacitor Suppliers and Custom EMI Suppression Capacitor Manufacturers.

We always adhere to the cooperation of advanced automation and industrialization. the company continues to introduce domestic and foreign outstanding production equipment, while self-developed production management software, enterprise collaborative management to scientific and efficient operation, has achieved 1 billion/annual production capacity breakthrough, and maintains an orderly rise.

Walson Electronics products have covered more industries, including new energy and power industry, Photovoltaic inverters, LED lighting, household appliances and various power sources and other industries.

Adhering to the concept of innovative technology, honest service and professional quality, Walson Electronics pushes forward capacitor products continuously and is sure to become the industry pioneer with innovative advantages.

-

In today's digital era, the demand for electronic products continues to grow, and the demand for high performance, thinn...

READ MORE -

With the increasing global demand for renewable energy and the reduction of traditional fossil energy, the development o...

READ MORE -

In modern society, the stable operation of critical infrastructure is crucial to the normal functioning of society. Thes...

READ MORE -

Smartphones have become an indispensable part of modern life. They are not only communication tools, but also a comprehe...

READ MORE

How do EMI suppression capacitors function to mitigate electromagnetic interference (EMI) in electronic circuits and systems?

Filtering High-Frequency Signals: EMI suppression capacitors are designed to exhibit low impedance at high frequencies, effectively acting as a short circuit for high-frequency noise signals. This allows them to divert EMI away from sensitive components or circuits, preventing interference with their operation.

Absorbing and Filtering Noise: Capacitors in EMI suppression circuits absorb and store electrical charge, effectively filtering out noise signals from the power supply or signal lines. This helps to smooth out voltage fluctuations and attenuate high-frequency noise, improving the overall signal quality and reliability of the electronic system.

Blocking DC and Low-Frequency Signals: While EMI suppression capacitors offer low impedance at high frequencies, they typically present high impedance at DC and low frequencies. This allows them to block DC and low-frequency signals while allowing high-frequency noise to pass through, thus isolating sensitive components from EMI.

简体中文

简体中文 English

English Español

Español