ABOUT US

Focused on Electronic Components Manufacturing for 20 Years.

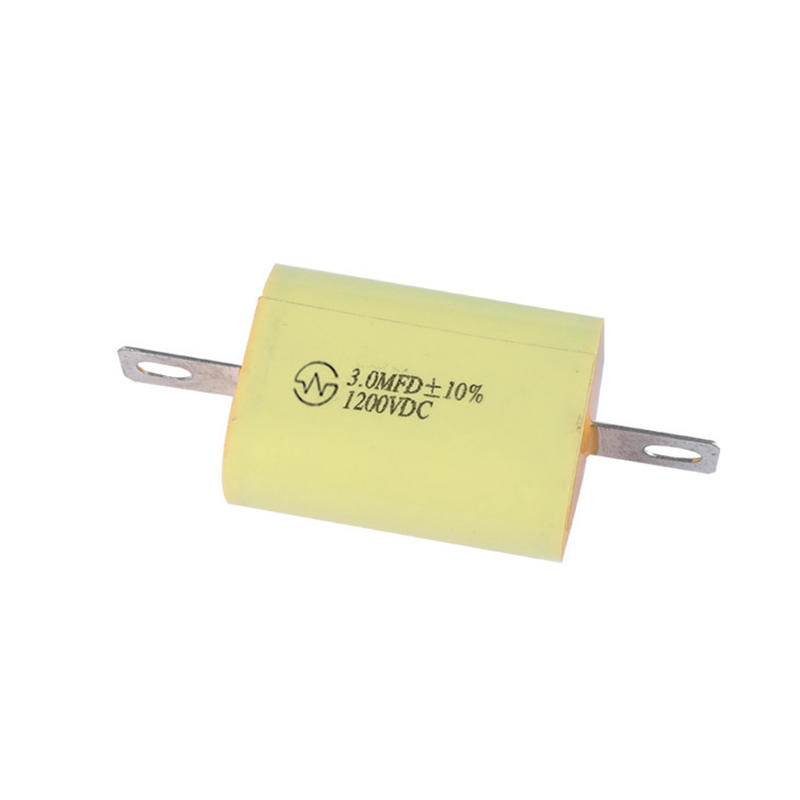

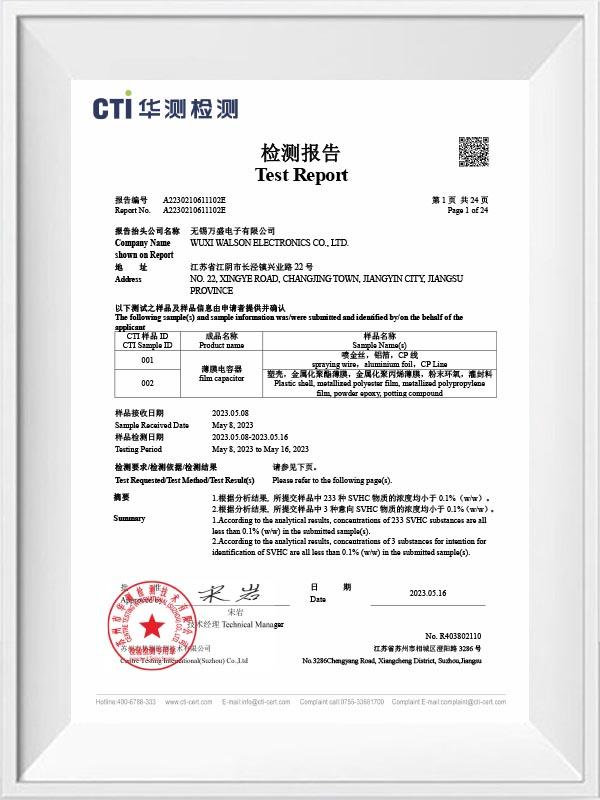

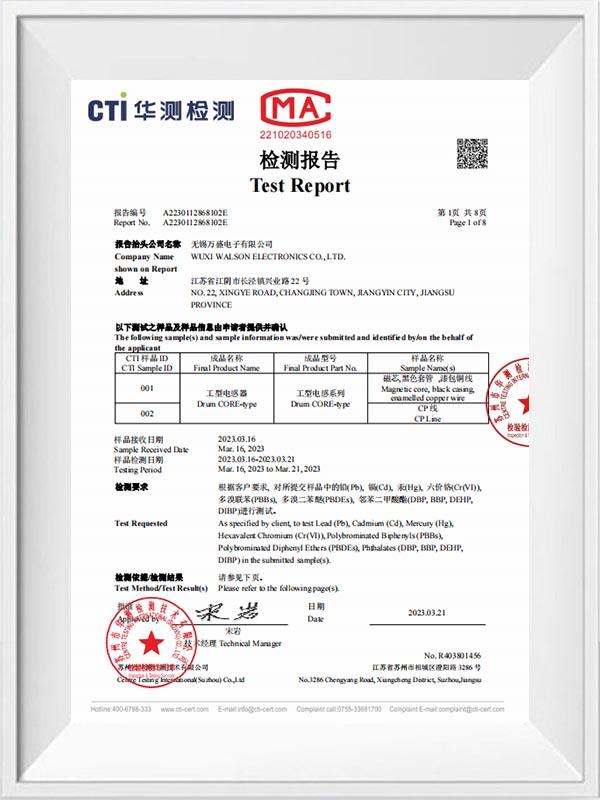

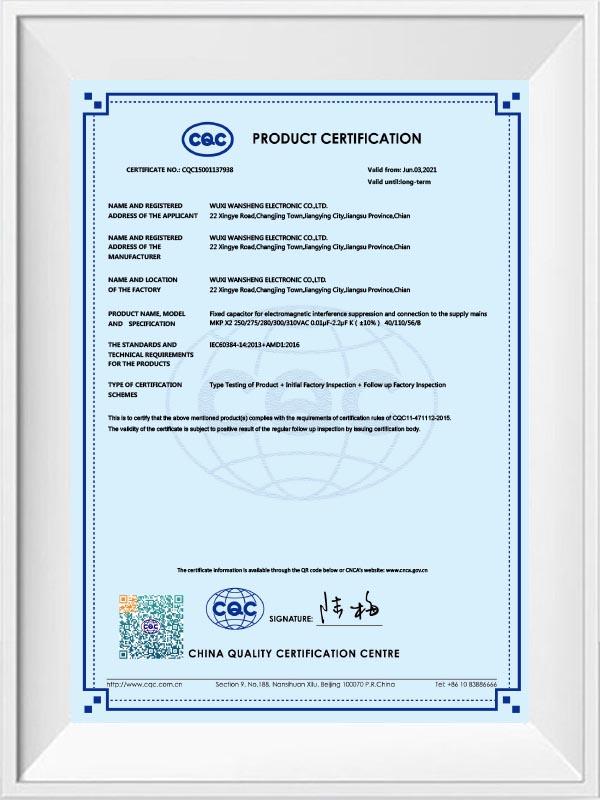

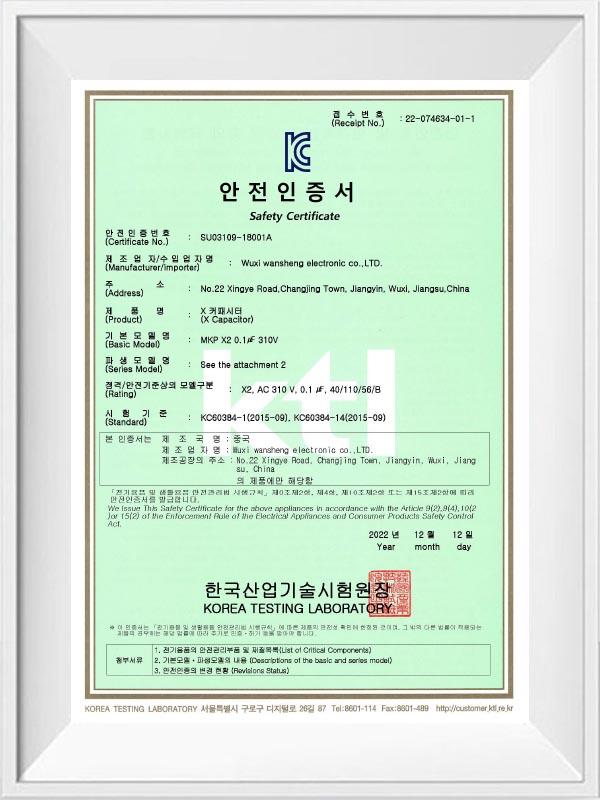

Walson Electronics was established in 2001, with more than 20 years of experience in R&D, manufacturing, sale and service of film capacitors. We are Custom IGBT Snubber Film Capacitor Suppliers and Custom Resonant Capacitor Manufacturers.

We always adhere to the cooperation of advanced automation and industrialization. the company continues to introduce domestic and foreign outstanding production equipment, while self-developed production management software, enterprise collaborative management to scientific and efficient operation, has achieved 1 billion/annual production capacity breakthrough, and maintains an orderly rise.

Walson Electronics products have covered more industries, including new energy and power industry, Photovoltaic inverters, LED lighting, household appliances and various power sources and other industries.

Adhering to the concept of innovative technology, honest service and professional quality, Walson Electronics pushes forward capacitor products continuously and is sure to become the industry pioneer with innovative advantages.

-

In today's digital era, the demand for electronic products continues to grow, and the demand for high performance, thinn...

READ MORE -

With the increasing global demand for renewable energy and the reduction of traditional fossil energy, the development o...

READ MORE -

In modern society, the stable operation of critical infrastructure is crucial to the normal functioning of society. Thes...

READ MORE -

Smartphones have become an indispensable part of modern life. They are not only communication tools, but also a comprehe...

READ MORE

How do IGBT snubber film capacitors contribute to improving the performance and reliability of insulated-gate bipolar transistors (IGBTs) in power electronic systems?

Voltage Spike Suppression: During the switching transitions of IGBTs, voltage spikes can occur due to parasitic inductances in the circuit. IGBT snubber film capacitors are connected in parallel with the IGBT to absorb these voltage spikes, effectively suppressing them and protecting the transistor from voltage overstress. This helps prevent premature breakdown of the IGBT and minimizes the risk of device failure.

Reduced Switching Losses: Voltage spikes during IGBT switching events can lead to increased switching losses, which can degrade system efficiency and reliability. By providing a low-impedance path for the voltage spikes, snubber capacitors help reduce the amplitude and duration of voltage transients, thereby lowering the switching losses associated with IGBT turn-off events. This results in improved overall system efficiency and reduced thermal stress on the IGBT.

Ringing Damping: IGBTs can exhibit ringing phenomena during turn-off due to the interaction between the parasitic inductances and capacitances in the circuit. This ringing can lead to excessive voltage stress on the IGBT and potentially cause device failure. Snubber capacitors are designed to dampen the ringing oscillations by providing a controlled discharge path for the energy stored in the circuit, thereby mitigating voltage overshoot and protecting the IGBT from overstress.

How do advancements in capacitor technology, such as new film materials or construction techniques, contribute to improved performance and reliability of IGBT snubber capacitors in power electronics?

Improved Dielectric Materials: The use of advanced dielectric materials with enhanced properties, such as higher dielectric strength, lower dielectric loss, and better self-healing characteristics, can significantly improve the performance and reliability of IGBT snubber capacitors. For example, the adoption of newer polymer film materials, such as polypropylene (PP) or metallized polyethylene terephthalate (PET), can offer superior electrical properties compared to traditional materials, leading to reduced ESR (Equivalent Series Resistance) and improved voltage handling capabilities.

Higher Voltage Ratings: Advancements in capacitor technology enable the development of IGBT snubber capacitors with higher voltage ratings, allowing them to withstand higher peak voltages and transient events commonly encountered in power electronics applications. This increases the robustness and reliability of the capacitors, reducing the risk of voltage overstress and premature failure of the IGBTs.

Reduced Size and Weight: Innovative construction techniques, such as thinner film layers, advanced metallization processes, and optimized winding patterns, enable the production of IGBT snubber capacitors with smaller form factors and reduced weight. This not only saves valuable space in power electronic systems but also improves thermal management and enhances overall system reliability by minimizing heat generation and component stress.

简体中文

简体中文 English

English Español

Español