ABOUT US

Focused on Electronic Components Manufacturing for 20 Years.

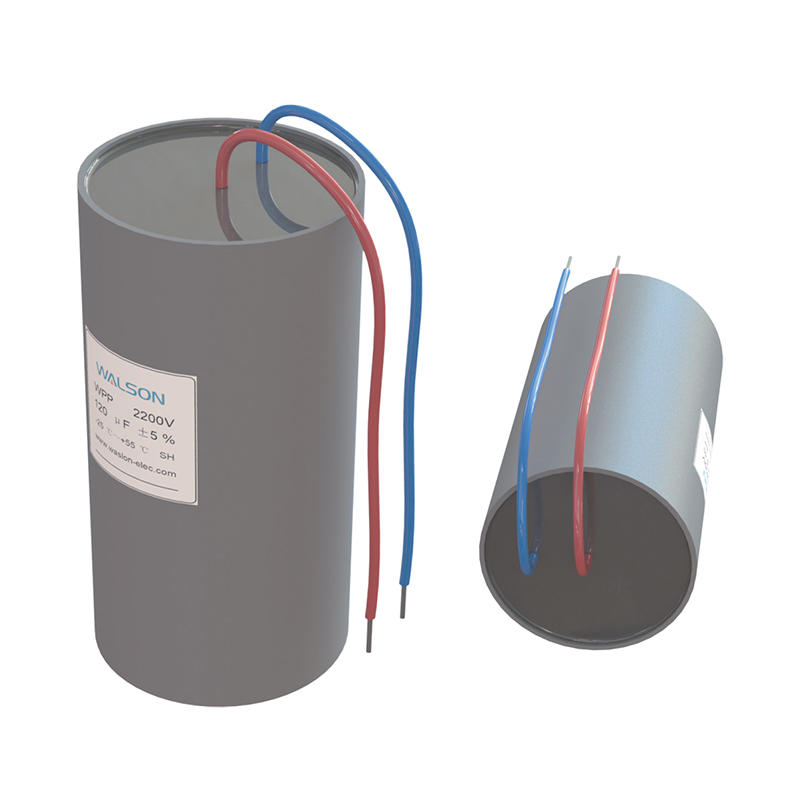

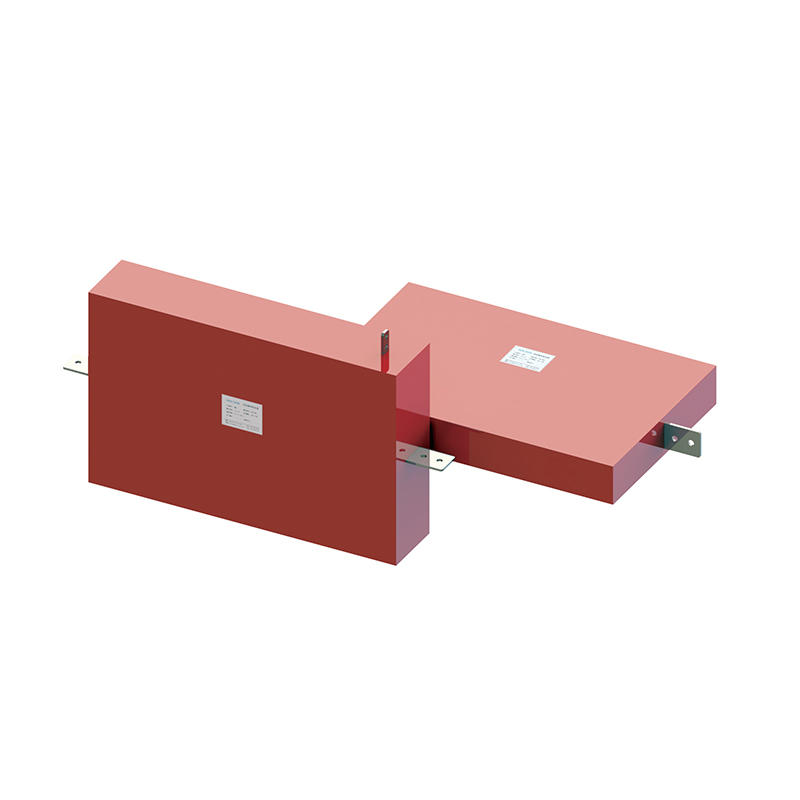

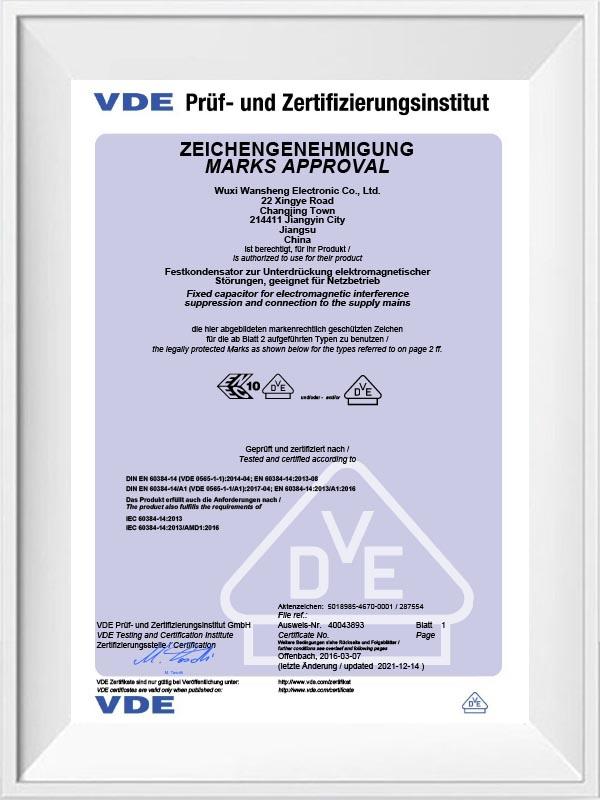

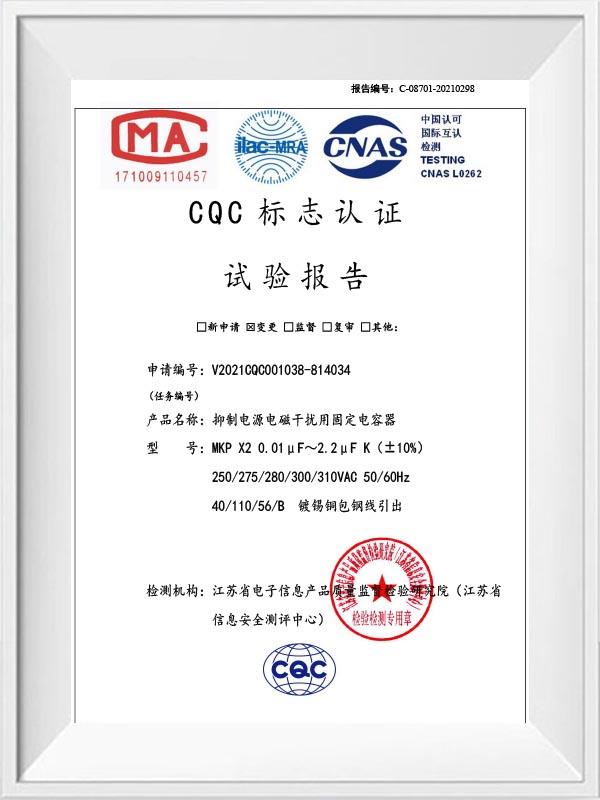

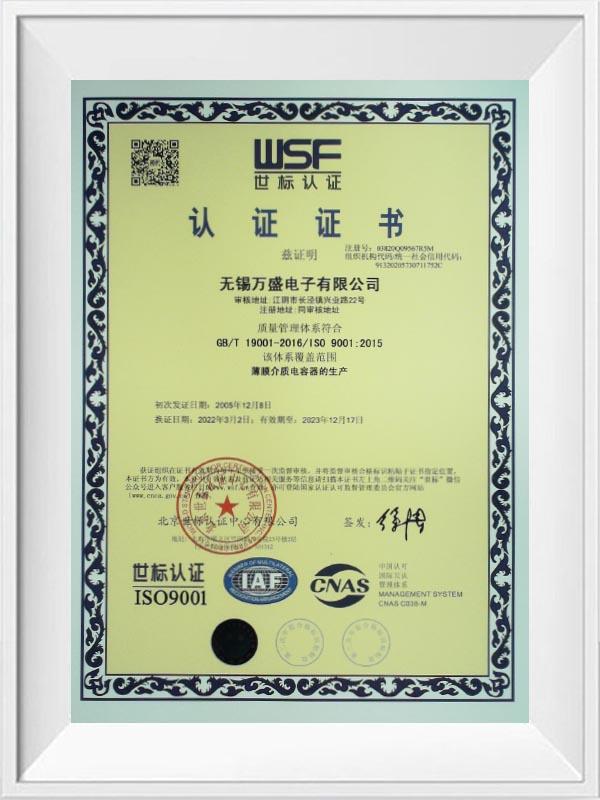

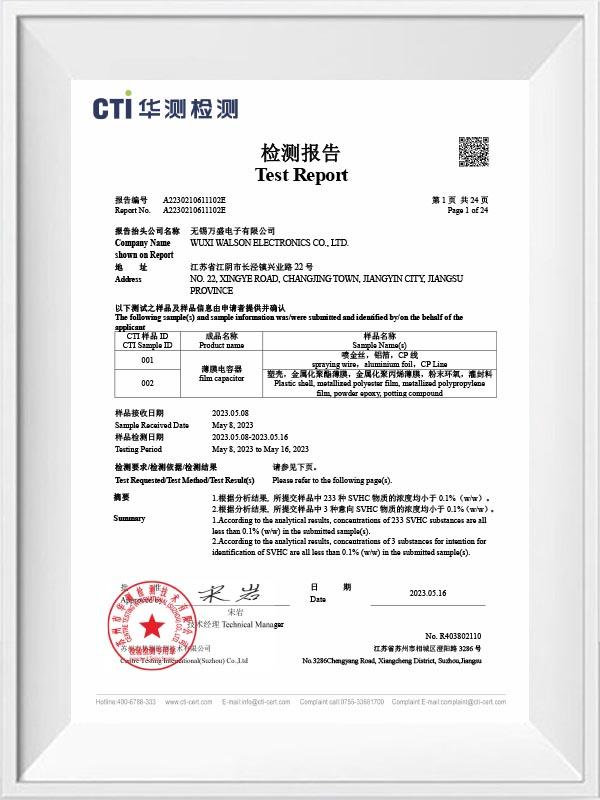

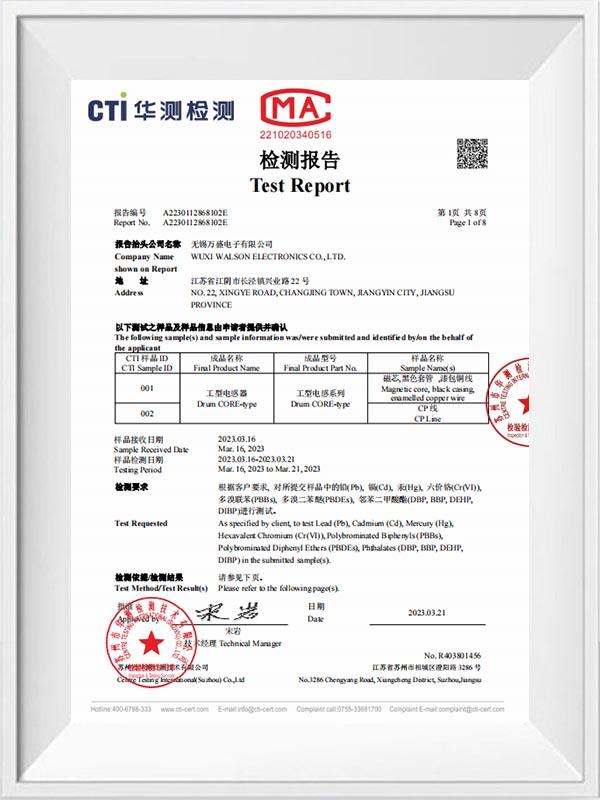

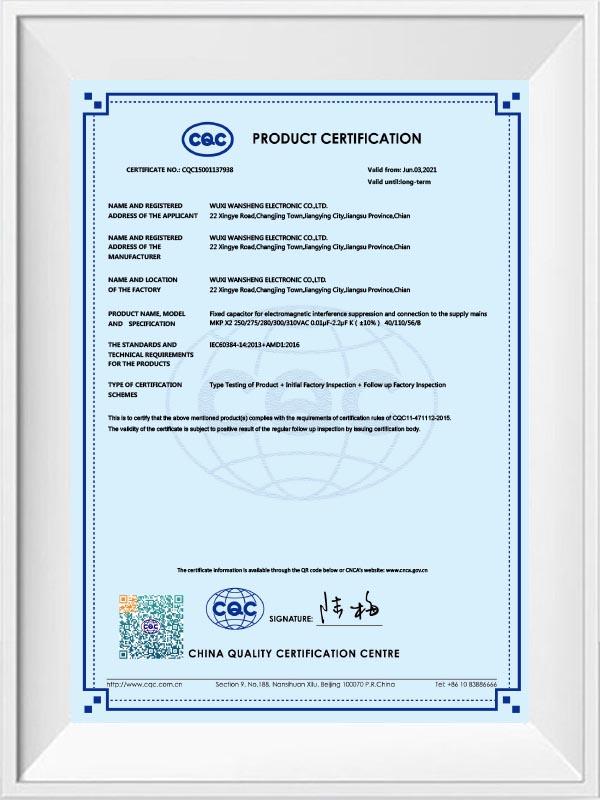

Walson Electronics was established in 2001, with more than 20 years of experience in R&D, manufacturing, sale and service of film capacitors. We are Custom Energy Storage/Pulse Capacitor Suppliers and Custom Energy Storage/Pulse Capacitor Manufacturers.

We always adhere to the cooperation of advanced automation and industrialization. the company continues to introduce domestic and foreign outstanding production equipment, while self-developed production management software, enterprise collaborative management to scientific and efficient operation, has achieved 1 billion/annual production capacity breakthrough, and maintains an orderly rise.

Walson Electronics products have covered more industries, including new energy and power industry, Photovoltaic inverters, LED lighting, household appliances and various power sources and other industries.

Adhering to the concept of innovative technology, honest service and professional quality, Walson Electronics pushes forward capacitor products continuously and is sure to become the industry pioneer with innovative advantages.

-

In today's digital era, the demand for electronic products continues to grow, and the demand for high performance, thinn...

READ MORE -

With the increasing global demand for renewable energy and the reduction of traditional fossil energy, the development o...

READ MORE -

In modern society, the stable operation of critical infrastructure is crucial to the normal functioning of society. Thes...

READ MORE -

Smartphones have become an indispensable part of modern life. They are not only communication tools, but also a comprehe...

READ MORE

What are the key characteristics and specifications to consider when selecting energy storage/pulse capacitors for specific pulse power applications, such as pulsed lasers, electromagnetic railguns, or particle accelerators?

Capacitance (C): The capacitance of the capacitor determines the amount of energy it can store. The required capacitance depends on the pulse energy and duration needed for the application. Larger capacitance values are typically required for applications with high pulse energy and longer pulse durations.

Voltage Rating (V): The voltage rating of the capacitor should be sufficient to withstand the peak voltage levels experienced during operation without breakdown. It should exceed the maximum voltage applied across the capacitor during operation, including any voltage spikes or transients.

Energy Density: Energy density refers to the amount of energy that can be stored per unit volume or mass of the capacitor. High energy density capacitors allow for compact designs and are desirable for applications with space constraints.

Discharge Rate: The discharge rate, often specified as the maximum pulse current or peak discharge power, determines how quickly the capacitor can deliver its stored energy. It should be matched to the pulse duration and peak power requirements of the application.

Pulse Repetition Rate: Some applications require capacitors capable of handling high pulse repetition rates. The capacitor should be able to discharge and recharge rapidly without significant degradation in performance or reliability.

Temperature Stability: Capacitors should maintain stable performance over the operating temperature range of the application. Temperature stability is critical to ensure consistent pulse energy delivery and reliability under varying environmental conditions.

What thermal management techniques are employed to ensure proper heat dissipation and temperature stability in energy storage/pulse capacitors operating under high-power conditions?

Heat Sink Integration: Heat sinks are commonly used to dissipate heat from energy storage/pulse capacitors. These heat sinks can be made of materials with high thermal conductivity, such as aluminum or copper, and are typically attached to the capacitor casing or terminals. Heat sinks increase the surface area available for heat transfer and enhance overall thermal performance.

Forced Air Cooling: Fans or blowers can be integrated into the system to provide forced air cooling for energy storage/pulse capacitors. Airflow generated by the fans helps remove heat from the capacitors and maintains temperature stability. This method is particularly effective for applications with high power dissipation requirements.

Liquid Cooling: Liquid cooling systems, such as coolant loops or immersion cooling, can be used to remove heat from energy storage/pulse capacitors. Liquid coolant, such as water or specialized dielectric fluids, circulates around the capacitors, absorbing heat and dissipating it through a heat exchanger or radiator. Liquid cooling systems offer efficient heat removal and can be especially beneficial for applications with high-power densities.

简体中文

简体中文 English

English Español

Español