ABOUT US

Focused on Electronic Components Manufacturing for 20 Years.

Walson Electronics was established in 2001, with more than 20 years of experience in R&D, manufacturing, sale and service of film capacitors. We are Custom Customized Capacitor Suppliers and Custom Customized Capacitor Manufacturers.

We always adhere to the cooperation of advanced automation and industrialization. the company continues to introduce domestic and foreign outstanding production equipment, while self-developed production management software, enterprise collaborative management to scientific and efficient operation, has achieved 1 billion/annual production capacity breakthrough, and maintains an orderly rise.

Walson Electronics products have covered more industries, including new energy and power industry, Photovoltaic inverters, LED lighting, household appliances and various power sources and other industries.

Adhering to the concept of innovative technology, honest service and professional quality, Walson Electronics pushes forward capacitor products continuously and is sure to become the industry pioneer with innovative advantages.

-

In today's digital era, the demand for electronic products continues to grow, and the demand for high performance, thinn...

READ MORE -

With the increasing global demand for renewable energy and the reduction of traditional fossil energy, the development o...

READ MORE -

In modern society, the stable operation of critical infrastructure is crucial to the normal functioning of society. Thes...

READ MORE -

Smartphones have become an indispensable part of modern life. They are not only communication tools, but also a comprehe...

READ MORE

How do customized capacitors address specific performance requirements and design challenges in various electronic applications compared to off-the-shelf capacitor solutions?

Precise Specification Matching: Customized capacitors are designed to precisely match the specifications and performance requirements of the electronic system or application. This includes parameters such as capacitance, voltage rating, temperature range, and physical dimensions. Off-the-shelf capacitors may not always offer the exact combination of specifications needed for specialized applications.

Optimized Performance: Customized capacitors are engineered to deliver optimized performance in specific operating conditions, such as high temperature, high frequency, or high voltage environments. They may incorporate specialized dielectric materials, electrode configurations, or construction techniques to achieve superior performance compared to standard capacitors.

Unique Form Factors: Customized capacitors can be designed in unique form factors and shapes to fit into space-constrained or unconventional layouts within electronic systems. This flexibility allows for efficient utilization of available space and integration into complex assemblies where off-the-shelf capacitors may not be suitable.

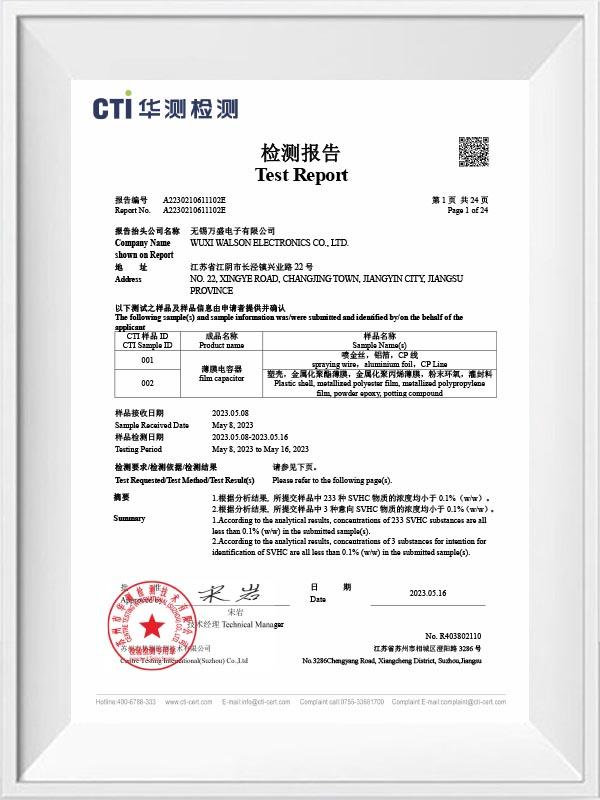

Enhanced Reliability: Customized capacitors are often built with enhanced reliability features to withstand harsh environmental conditions, mechanical stresses, or electrical stresses encountered in specific applications. This may include robust construction, improved insulation, or additional protective coatings to enhance durability and longevity.

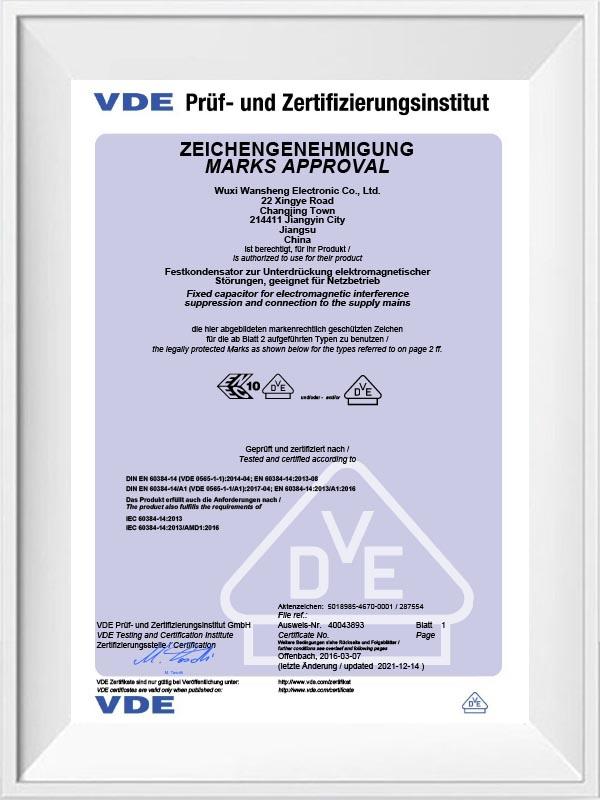

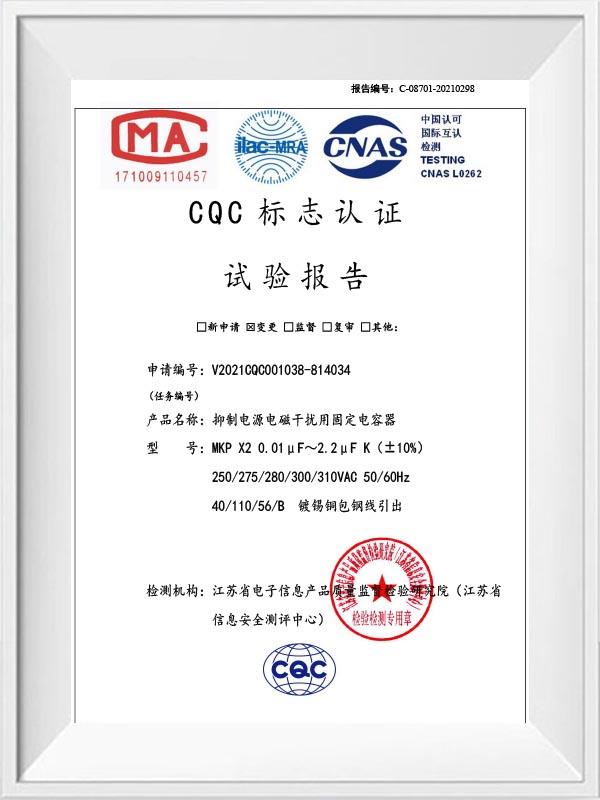

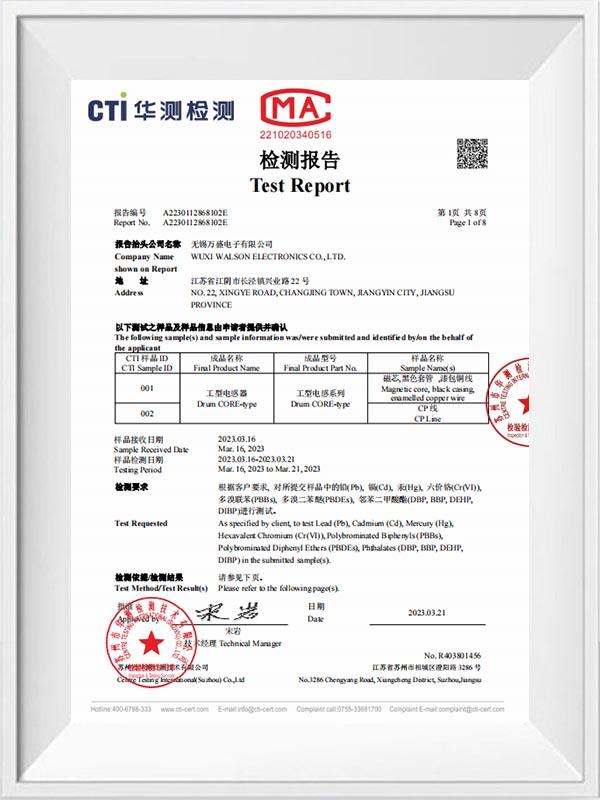

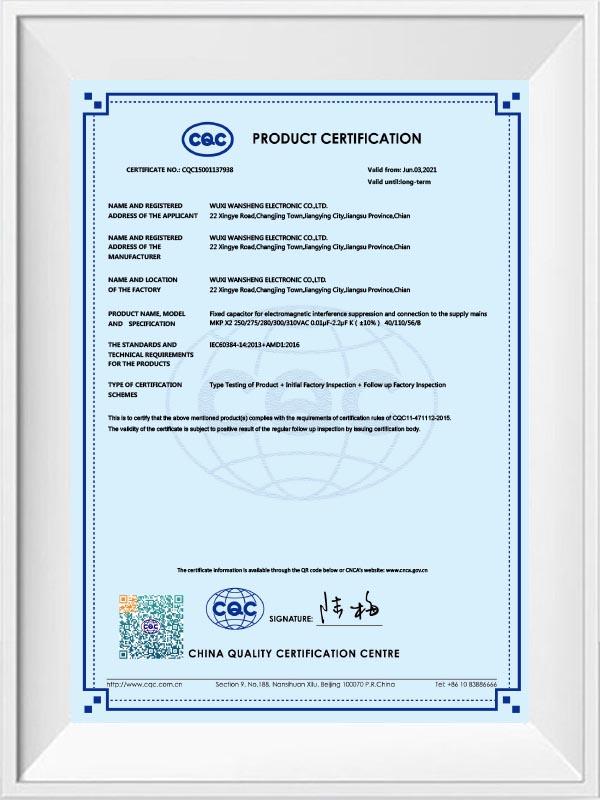

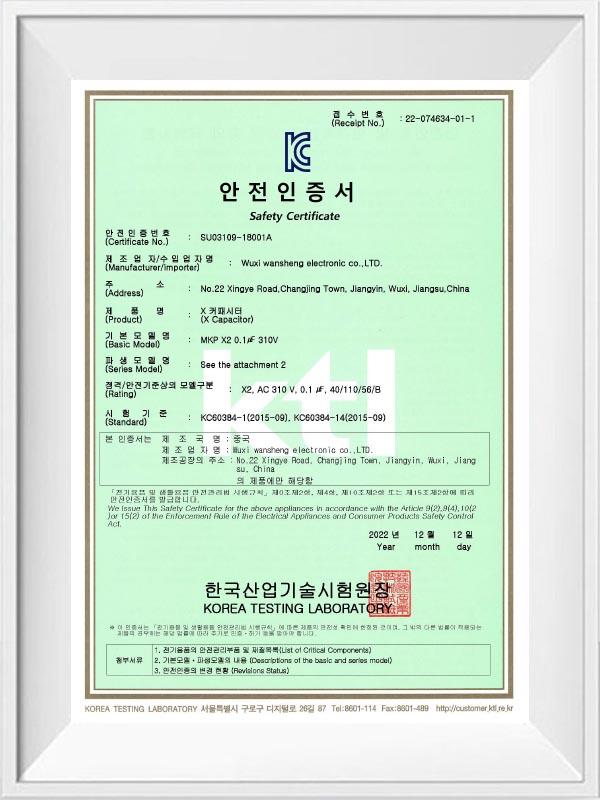

Are there any industry standards or regulations governing the design and manufacturing of customized capacitors, and what compliance measures should manufacturers adhere to?

General Capacitor Standards: Capacitor manufacturers often adhere to international standards governing capacitor design, testing, and performance characteristics. Examples include:

IEC 60384 series: International standards for fixed capacitors for use in electronic equipment, covering various aspects such as electrical properties, safety requirements, and testing methods.

ANSI/IEEE standards: Standards published by the Institute of Electrical and Electronics Engineers (IEEE) and the American National Standards Institute (ANSI) may also be relevant, especially for high-voltage or high-power capacitors.

Application-Specific Standards: Depending on the intended application of the customized capacitors, manufacturers may need to comply with industry-specific standards and regulations. For example:

Aerospace: Capacitors used in aerospace applications must often meet stringent standards such as those set by the Federal Aviation Administration (FAA), European Aviation Safety Agency (EASA), or military specifications like MIL-PRF-49470.

Automotive: Capacitors for automotive applications need to comply with standards such as AEC-Q200, which specifies rigorous testing requirements for electronic components used in automotive systems.

Medical: Capacitors used in medical devices must adhere to standards such as ISO 13485 for quality management systems in medical device manufacturing, as well as specific regulations like FDA requirements in the United States or CE marking in Europe.

简体中文

简体中文 English

English Español

Español