ABOUT US

Focused on Electronic Components Manufacturing for 20 Years.

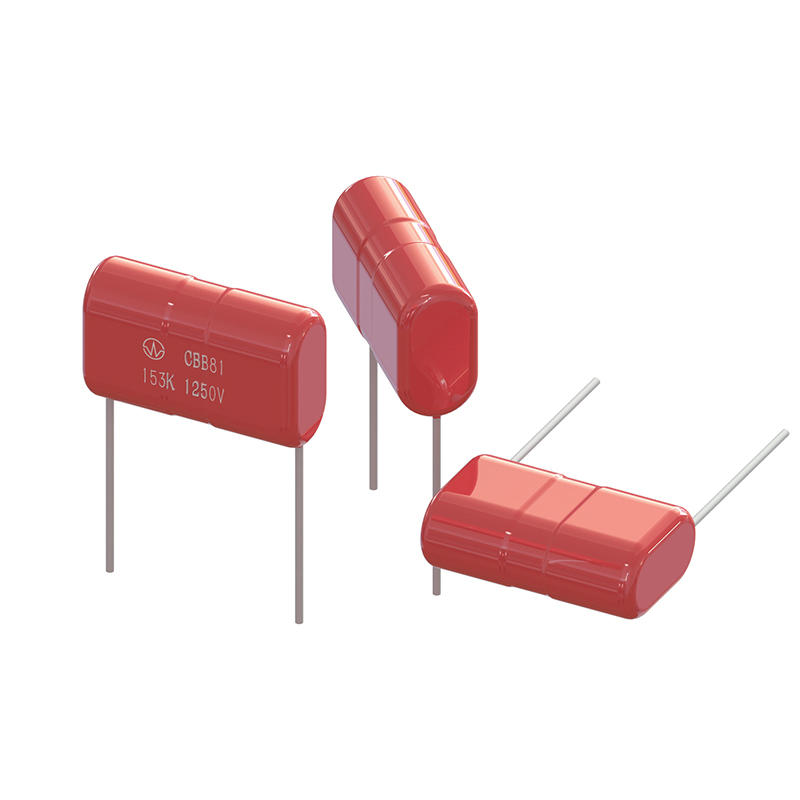

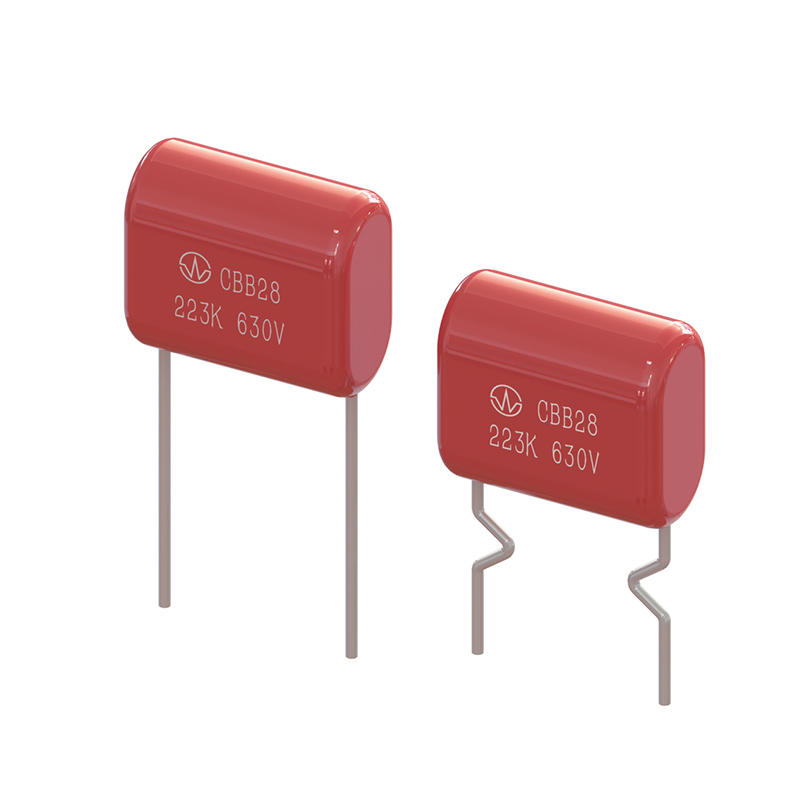

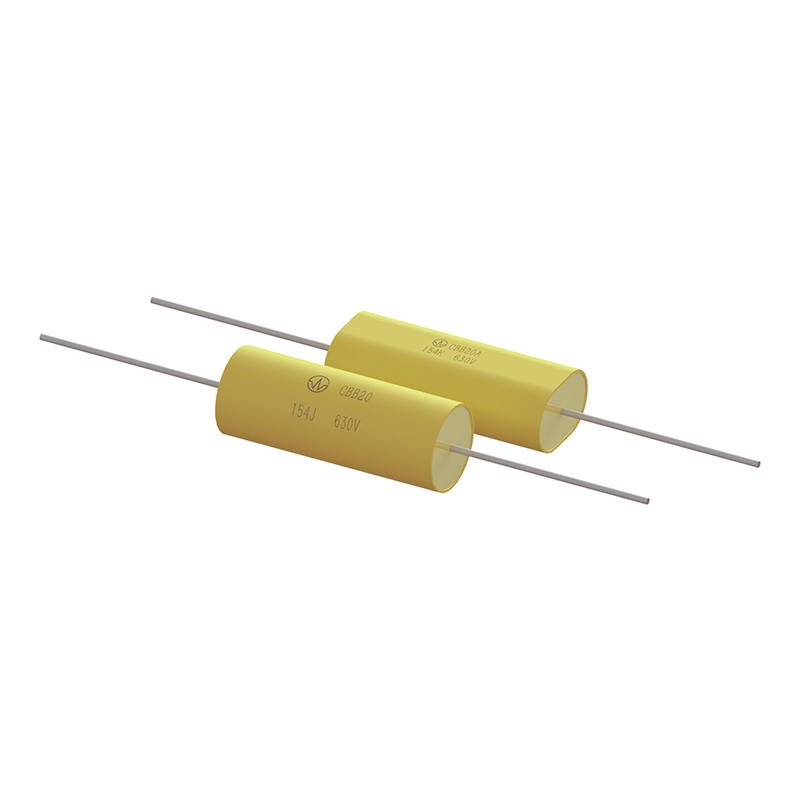

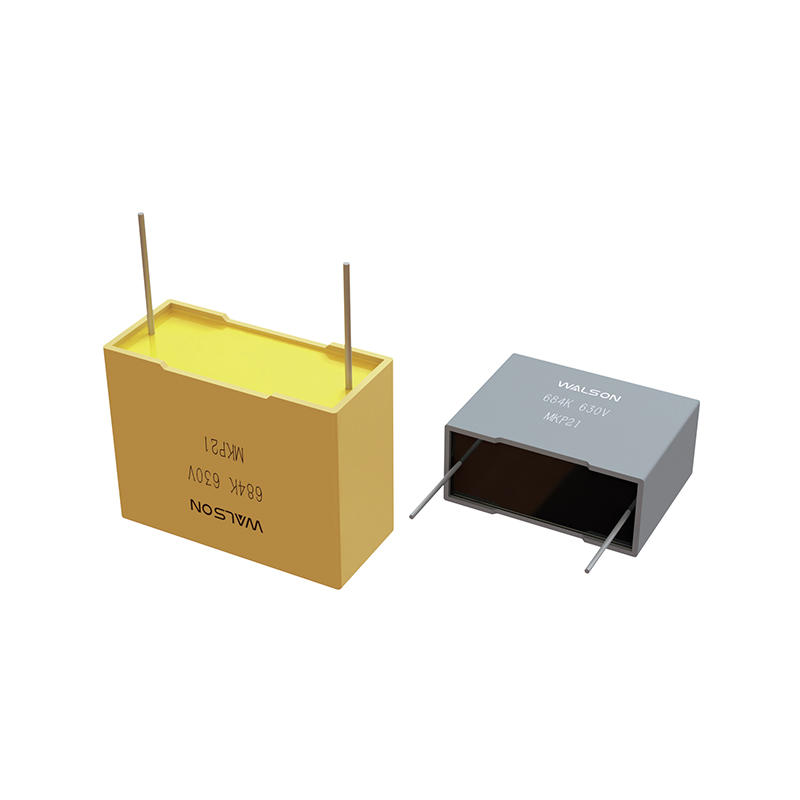

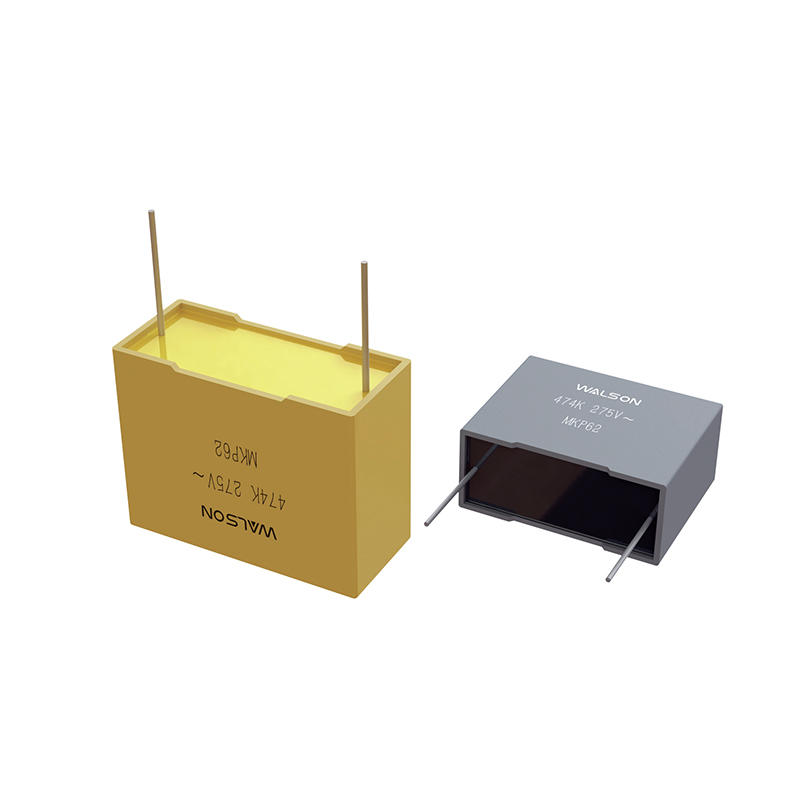

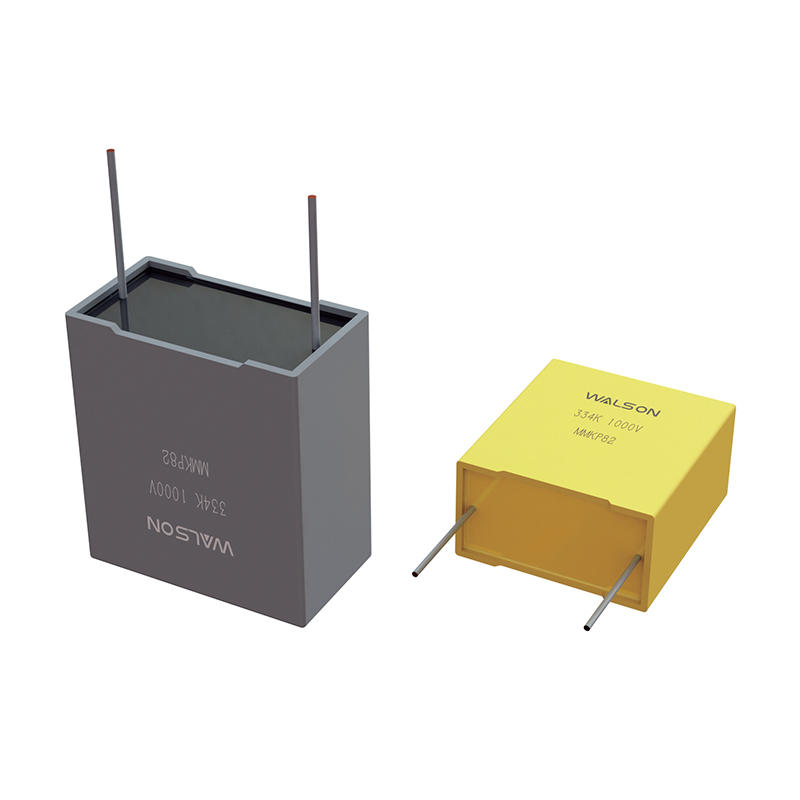

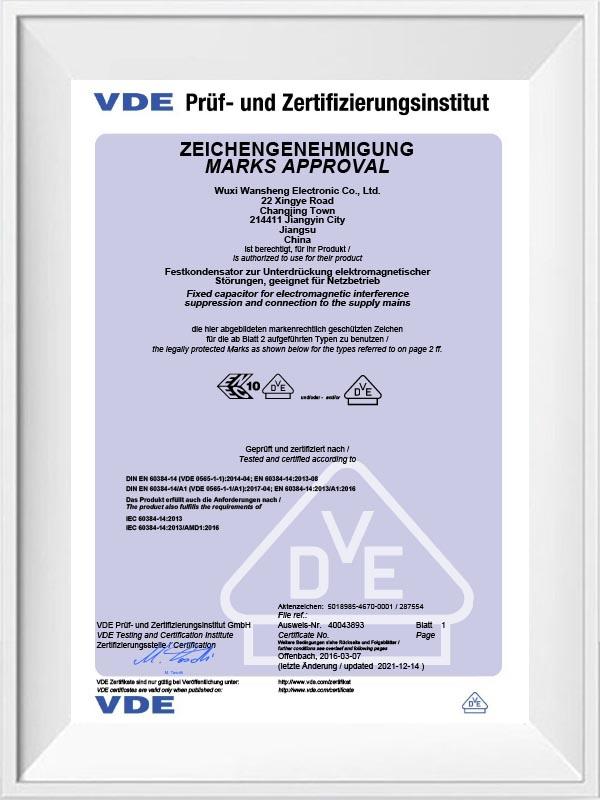

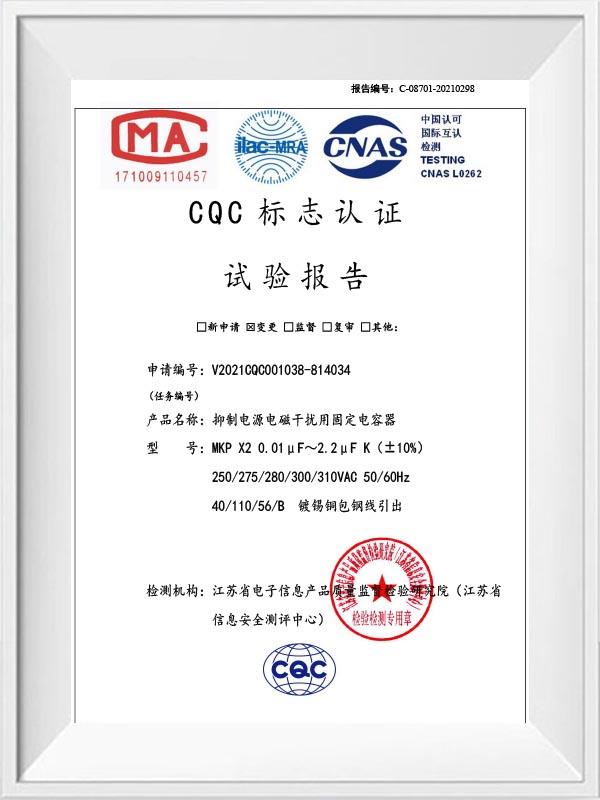

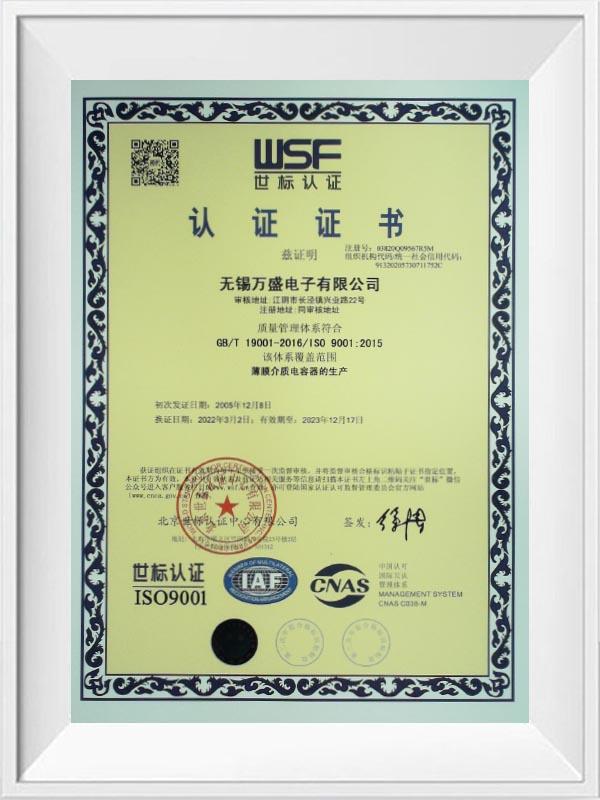

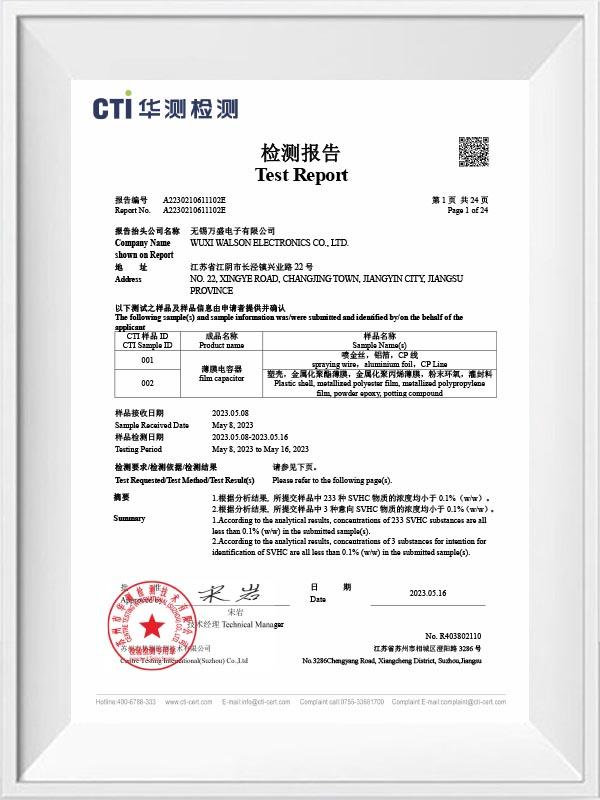

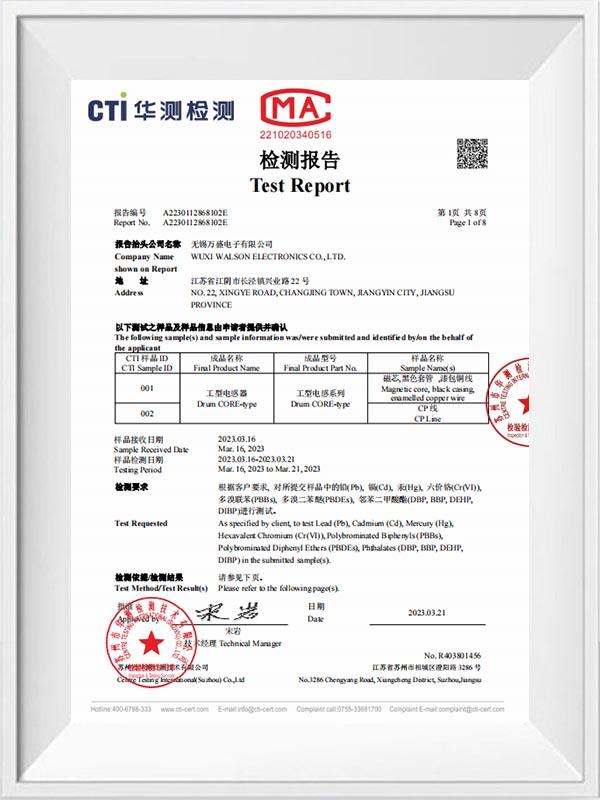

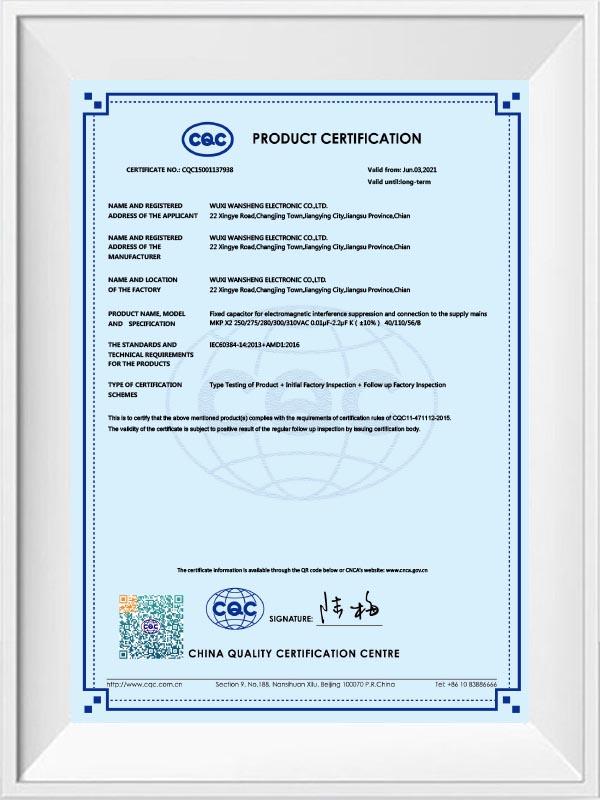

Walson Electronics was established in 2001, with more than 20 years of experience in R&D, manufacturing, sale and service of film capacitors. We are Custom Polypropylene Film Capacitor Suppliers and Custom CBB Film Capacitor Manufacturers.

We always adhere to the cooperation of advanced automation and industrialization. the company continues to introduce domestic and foreign outstanding production equipment, while self-developed production management software, enterprise collaborative management to scientific and efficient operation, has achieved 1 billion/annual production capacity breakthrough, and maintains an orderly rise.

Walson Electronics products have covered more industries, including new energy and power industry, Photovoltaic inverters, LED lighting, household appliances and various power sources and other industries.

Adhering to the concept of innovative technology, honest service and professional quality, Walson Electronics pushes forward capacitor products continuously and is sure to become the industry pioneer with innovative advantages.

-

In today's digital era, the demand for electronic products continues to grow, and the demand for high performance, thinn...

READ MORE -

With the increasing global demand for renewable energy and the reduction of traditional fossil energy, the development o...

READ MORE -

In modern society, the stable operation of critical infrastructure is crucial to the normal functioning of society. Thes...

READ MORE -

Smartphones have become an indispensable part of modern life. They are not only communication tools, but also a comprehe...

READ MORE

How does the dielectric constant of polypropylene film capacitors influence their performance and suitability for different electronic circuits and systems?

Capacitance Value: The dielectric constant directly influences the capacitance value of the capacitor. Polypropylene film capacitors typically have a relatively high dielectric constant compared to other capacitor types, which allows them to achieve higher capacitance values in smaller physical sizes. This makes them suitable for applications where space constraints are a concern.

Frequency Response: The dielectric constant affects the frequency response of the capacitor. Polypropylene film capacitors typically have a stable dielectric constant over a wide frequency range, making them suitable for applications requiring stable capacitance values across different frequency bands. This makes them ideal for use in filter circuits, resonant circuits, and high-frequency applications.

Voltage Stability: The dielectric constant also influences the voltage stability of the capacitor. Polypropylene film capacitors exhibit low dielectric absorption and high breakdown voltage characteristics, allowing them to maintain stable capacitance values even under high voltage conditions. This makes them suitable for use in high-voltage applications such as power supplies, motor drives, and inverters.

Temperature Stability: The dielectric constant of polypropylene film capacitors remains relatively stable over a wide temperature range. This temperature stability ensures consistent performance of the capacitor across different operating temperatures, making them suitable for use in harsh environmental conditions and temperature-sensitive applications.

What measures are taken during the manufacturing of polypropylene film capacitors to ensure high insulation resistance and low dielectric absorption characteristics?

Material Selection: High-quality polypropylene film is chosen as the dielectric material due to its excellent electrical properties, including high insulation resistance and low dielectric absorption. The film is carefully selected to meet stringent specifications for thickness, purity, and uniformity.

Metallization Process: Metallization of the polypropylene film is performed using high-purity metal electrodes to ensure good contact and adhesion between the metal and dielectric layers. This metallization process is critical for achieving low ESR (Equivalent Series Resistance) and high insulation resistance.

Winding and Stacking: The polypropylene film is wound or stacked with the metal electrodes to form the capacitor's construction. Special attention is paid to maintaining uniform tension and alignment during the winding or stacking process to minimize defects and ensure consistent electrical properties throughout the capacitor.

Impregnation and Encapsulation: Some polypropylene film capacitors undergo impregnation with a dielectric fluid or encapsulation with a protective material to enhance insulation resistance and minimize moisture absorption. This impregnation or encapsulation process helps to seal the capacitor and prevent moisture ingress, which can degrade insulation resistance over time.

简体中文

简体中文 English

English Español

Español